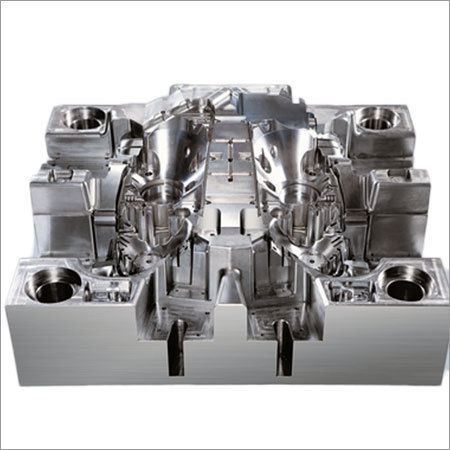

Front Grill Mould

Front Grill Mould Specification

- Working Process

- CNC Machining, EDM, Polishing

- Life Span

- More than 500,000 shots

- Core Material

- 718H Hardened Steel

- Tolerance

- 0.02 mm

- Mould Base

- P20 Steel

- Material

- ABS/PC/PP/PA6 (Depending on Requirement)

- Shaping Mode

- Injection Mould

- Punch Dies

- Multi-cavity with Replaceable Inserts

- Die Head

- Custom Designed, High Precision

- Mould Size

- Customized as per Front Grill Dimensions

- Cavity Number

- 1-4 Cavities (Customizable)

- Cooling System

- Optimized Water Channel Design

- Runner Type

- Hot Runner/Cold Runner System

- Ejection System

- Pin Ejection, Plate Ejection

- Lead Time

- 50-75 Days (Depending on Complexity)

- Application

- Automotive Front Grill Manufacturing

- Design Software

- UG, AutoCAD, Pro-E

- Surface Finish

- Mirror Polish or Textured as per Sample

- Mould Weight

- Approximately 1-4 Tons

Front Grill Mould Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

About Front Grill Mould

Front Grill Mould that we offer is designed for providing accurate shape, size and edge edges finish to front grill, used in various models of cars and other vehicles. This type of mould works with the support of sophisticated injection moulding machine. It is made of top-grade metal with progressive casting technique that make its dimension, strength and durability great. Comes in several dimensions and designs, the offered Front Grill Mould can be bought at competitive prices through this portal.

| Usage/Application | Molding Die |

Customizable for Your Needs

Adaptability is at the core of our Front Grill Mould. Whether you require 1 or 4 cavities, mirror polish or textured surfaces, we tailor the mould to exactly match your production requirements. By customizing the size and surface finish as per your sample, you receive the precise fit and aesthetics needed for your automotive front grills.

Superior Material and Engineering

Our moulds are engineered using high-grade materials, with P20 steel for the mould base and 718H hardened steel for the core. Supported by advanced design software (UG, AutoCAD, Pro-E), CNC machining, and EDM, each mould ensures long-term reliability and high precision. This combination guarantees a lifespan exceeding 500,000 shots, supporting robust, repetitive manufacturing cycles.

Optimized Performance and Efficiency

The hot runner/cold runner options, along with pin and plate ejection systems, provide efficient moulding and easy part removal. Optimized water channel design enhances cooling, leading to faster cycle times and improved product quality. Replaceable punch die inserts allow quick maintenance, reducing downtime and maximizing facility throughput.

FAQs of Front Grill Mould:

Q: How is the cavity number of the Front Grill Mould customized?

A: The cavity number is tailored based on your production volume requirements and grill design specifications. Whether you need 1 to 4 cavities, our team will design and fabricate the mould to suit your application for efficient manufacturing.Q: What surface finish options are available for the moulded front grills?

A: You can choose between mirror polish and textured finishes, both customizable as per your sample. This ensures that the final product matches your preferred aesthetic and functional requirements.Q: When can I expect the delivery of my custom Front Grill Mould?

A: The lead time ranges from 50 to 75 days, depending on the complexity and detailing of your order. Timelines are discussed and agreed upon during the design phase to ensure timely completion and delivery.Q: Where is the Front Grill Mould manufactured and supplied from?

A: Our moulds are manufactured, serviced, and supplied from India, leveraging modern engineering and manufacturing facilities to serve both domestic and international automotive industries.Q: What process is used to manufacture the Front Grill Mould?

A: Production involves advanced CNC machining, EDM (Electrical Discharge Machining), polishing, and high-precision die head design. This ensures optimal accuracy, durability, and surface finish for every mould produced.Q: How is the mould maintained for long lifespan and high shot counts?

A: The use of robust core and mould base materials, precision engineering, and replaceable punch die inserts enable easy maintenance and longevity, ensuring a lifespan exceeding 500,000 shots with consistent performance.Q: What are the benefits of using optimized water channel cooling in the mould design?

A: Optimized water channel cooling expedites heat dissipation during injection, resulting in faster cycle times, reduced risk of warping, and enhanced surface quality of the finished front grill parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Die and Mould Category

Headlight Die

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Punch Dies : Custom punch dies included for detailed cutouts and inserts.

Working Process : Other, Injection Molding and Precision Machining processes.

Material : Other, Steel for die and core; compatible with both thermoplastic and thermoset molding.

Life Span : Up to 500,000 cycles (depends on maintenance and material used).

Speaker Grill Door Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Punch Dies : Customizable

Working Process : Other, CNC Machining, EDM, Milling

Material : Other, Plastic, Steel

Life Span : 1,000,000 Shots

Plastic Die and Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Punch Dies : HighStrength Steel, Heat Treated

Working Process : Other, Injection Moulding

Material : Other, Plastic/Metal as required

Life Span : 300,000 1,000,000 shots

Tail Light Mould

Minimum Order Quantity : 1 Piece

Punch Dies : Customfit to design, Hardened steel

Working Process : Other, CNC Machining, EDM, Polishing, Heat Treatment

Material : Other, Highquality steel alloy (selected per application)

Life Span : 500,000 to 1,000,000 shots

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS