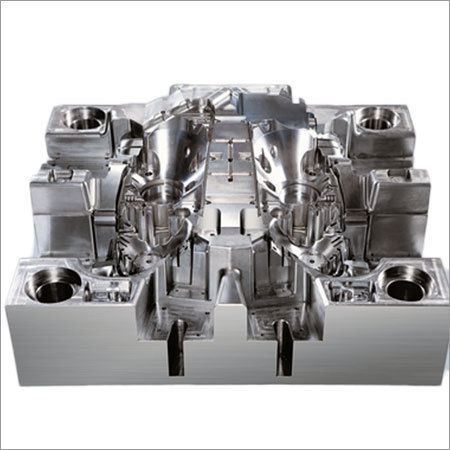

Speaker Grill Door Mould

Price 10000-1000000 INR/ Piece

Speaker Grill Door Mould Specification

- Mould Base

- P20 Steel

- Tolerance

- 0.01 mm

- Life Span

- 1,000,000 Shots

- Core Material

- H13 Steel

- Working Process

- CNC Machining, EDM, Milling

- Material

- Plastic, Steel

- Shaping Mode

- Injection Mould

- Punch Dies

- Customizable

- Die Head

- High Precision

- Mould Cavity

- Single/Multi Cavity

- Mould Weight

- 400-800 kg

- Color Support

- Custom colors available

- Mould Finish

- Fine Textured

- Application

- Automotive Door Speaker Grills

- Cycle Time

- 30-45 seconds

- Mounting Type

- Bolted

- Runner Type

- Hot/Cold Runner

- Lead Time

- 30-45 days

- Surface Treatment

- Polished, Nitrided

Speaker Grill Door Mould Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

About Speaker Grill Door Mould

Door Mould with Speaker Grill that offered by us is designed for giving world-class finish, shape and size to car door having speaker grill. This is a key component of heavy duty moulding machine, which uses it for casting door by injecting molten metal liquid. Made of high-grade aluminium metal with state-of-the-art fabrication technique, the Door Mould with Speaker Grill has excellent impact bearing strength, scratch resistance, and dimensional stability as tested by domain experts prior to deliver patrons.

| Usage/Application | Molding Die |

Engineered for Precision and Durability

Each Speaker Grill Door Mould is crafted to meet stringent automotive industry standards, using premium P20 steel and H13 core materials for exceptional strength and longevity. The moulds fine textured finish and high precision die head ensure superior product quality and excellent repeatability over its million-shot lifespan.

Flexible Configuration and Rapid Turnaround

Whether you require a single or multi-cavity mould, options are tailored to production scale and efficiency. Cycle times span just 30-45 seconds, and lead times for delivery are within 30-45 days, facilitating swift integration into your manufacturing pipeline. Customizable runner types and color support further enhance adaptability.

FAQs of Speaker Grill Door Mould:

Q: How is the Speaker Grill Door Mould manufactured?

A: The mould is produced using advanced CNC machining, EDM, and milling processes with high precision. Premium materials like P20 steel for the base and H13 steel for the core ensure durability, while polishing and nitriding treatments enhance both strength and finish.Q: What are the options for mould configuration and customization?

A: This mould is available in both single and multi-cavity versions and supports customization in color, punch die shapes, and runner types (hot or cold). Our team works with clients to deliver solutions tailored to their specific automotive speaker grill requirements.Q: When can I expect delivery after placing an order?

A: Standard lead times for the Speaker Grill Door Mould range from 30 to 45 days. This includes design approval, manufacturing, treatment, and rigorous quality inspections to meet industry standards before shipment.Q: Where can this mould be applied?

A: Primarily designed for automotive door speaker grills, this mould is ideal for automotive OEMs and component suppliers requiring high-precision, durable tooling for plastic injection moulding of speaker grill covers.Q: What is the typical lifespan and maintenance required?

A: The mould is engineered for up to 1,000,000 shots, offering a long operational life with proper maintenance. Regular cleaning and lubrication, along with periodic inspections, will ensure the mould continues to perform reliably.Q: How does the surface treatment benefit production?

A: Polishing and nitriding create a fine textured mould finish that improves product aesthetics, reduces friction during part ejection, and extends tool life by increasing surface hardness and resistance to wear.Q: What advantages does using this mould provide?

A: With a tight tolerance of 0.01 mm and high-quality material construction, this mould delivers highly precise and consistent automotive speaker grills, minimizes production downtime, and allows for rapid, repeatable manufacturing cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Die and Mould Category

Headlight Die

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Tolerance : 0.01 mm for tight dimensional accuracy.

Material : Other, Steel for die and core; compatible with both thermoplastic and thermoset molding.

Mould Base : Mild Steel (MS), Precisely machined base plate offers high stability and durability.

Die Head : Alloy Steel Die Head optimized for headlamp geometry.

Plastic Die and Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Tolerance : 0.01 mm

Material : Other, Plastic/Metal as required

Mould Base : Steel, Standard Mould Base

Die Head : Precision Machined, Customizable

Front Grill Mould

Minimum Order Quantity : 1 , , Piece

Tolerance : 0.02 mm

Material : Other, ABS/PC/PP/PA6 (Depending on Requirement)

Mould Base : P20 Steel

Die Head : Custom Designed, High Precision

Tail Light Mould

Minimum Order Quantity : 1 Piece

Tolerance : 0.01 mm

Material : Other, Highquality steel alloy (selected per application)

Mould Base : 45# Steel (customizable as per requirement)

Die Head : Precision machined, High longevity steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS