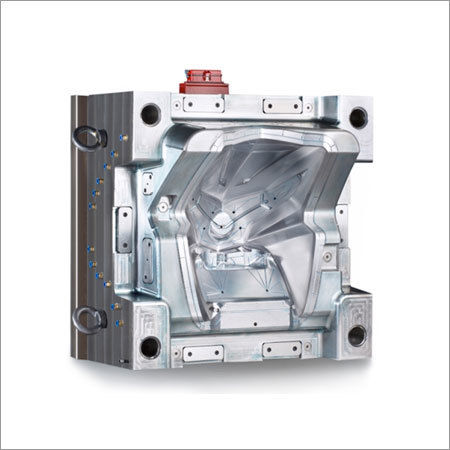

Motorcycle Front Cover Mould

Motorcycle Front Cover Mould Specification

- Working Process

- CNC Machining, EDM, Powder Coating

- Core Material

- Hardened Steel/718/NAK80/S136

- Life Span

- 300,000 500,000 shots

- Tolerance

- 0.01 mm

- Mould Base

- Standard P20 or as per customer requirement

- Material

- Plastic/ABS/PC

- Shaping Mode

- Injection Mould

- Punch Dies

- Multiple cavity

- Die Head

- Customizable as per design

- Delivery

- Wooden Case Packing

- Mould Weight

- 800 2000 kg

- Design Software

- UG, Pro/E, AutoCAD, SolidWorks

- Application

- Motorcycle Front Cover Production

- Surface Finish

- Polished, Textured, or Custom

- Ejection System

- Ejector Pin, Air Valve

- Mould Cavity

- Single or Multi Cavity available

- Customization

- Support OEM/ODM

- Runner System

- Hot or Cold Runner

- Lead Time

- 30 45 Days

Motorcycle Front Cover Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Week

About Motorcycle Front Cover Mould

Motorcycle Front Cover Mould that we put forward is made of chosen grade aluminium metal at high temperature. This type of mould can produce superior quality motorcycle front cover due to its A-one edges finish, ideal shape & size and great pressure bearing strength. It works well when fitted to modern injection moulding machine with help of reinforced fasteners. Having perfect dimension and compact size, it is simple to fit and maintain. Moreover, the Motorcycle Front Cover Mould can be availed customer-centric prices.

| Usage/Application | Molding Die |

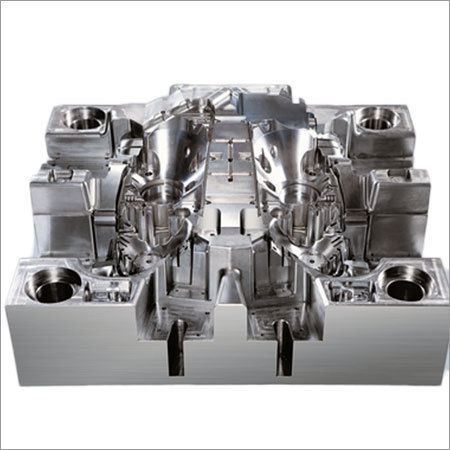

Precision Engineering for Reliable Production

Our motorcycle front cover moulds are built for accuracy, with tight tolerances of 0.01 mm. They undergo rigorous CNC machining and EDM processes, resulting in parts that precisely fit every design requirement. The use of high-grade core materials ensures robust performance and longevity, making these moulds suitable for extensive use in the motorcycle manufacturing industry.

Flexible Design and Customization

From single to multiple cavities and with a variety of surface finishes, these moulds allow flexibility in both volume and appearance. Our experienced engineering team utilizes premier design software to create custom solutions tailored to your project, supporting both OEM and ODM needs for ultimate adaptability.

Complete Support and Reliable Delivery

With standard lead times of 3045 days and secure wooden case packing, we ensure safe and timely delivery. Our after-sales service and technical support are designed to assist clients throughout the moulds operational life, ensuring smooth integration into your production process.

FAQs of Motorcycle Front Cover Mould:

Q: How is the motorcycle front cover mould customized for different applications?

A: We customize the mould based on client requirements regarding cavity numbers, runner system (hot or cold), surface finish, and core materials. Our team supports both OEM and ODM projects, ensuring the mould aligns perfectly with your motorcycle front cover production needs.Q: What is the typical lead time for manufacturing and delivering the mould?

A: The standard lead time ranges from 30 to 45 days, depending on the complexity of the mould and custom specifications. Delivery is carried out in secure wooden case packing to ensure the mould arrives in optimal condition.Q: Where does the production and supply of these moulds take place?

A: We are based in India and operate as a manufacturer, service provider, and supplier, catering to both domestic and international clients for motorcycle front cover production requirements.Q: What materials are used for the core and base of the mould?

A: The core materials commonly used include hardened steel, 718, NAK80, or S136, selected for strength and durability. The mould base is typically made from standard P20 steel or as specified by the customer to meet unique production demands.Q: How long is the lifespan of the mould, and what ensures its durability?

A: Each mould is designed for a lifespan of 300,000 to 500,000 shots, achieved through the use of premium-grade materials and precision processes like CNC machining, EDM, and appropriate surface coatings.Q: What are the main benefits of using this injection mould for motorcycle front covers?

A: The main advantages include high precision, flexible customization (surface finish, cavity, material), robust construction, and efficient production capability. This results in consistent part quality and reduced downtime for your manufacturing operations.Q: What design software is utilized during the mould design process?

A: We employ leading industry design software such as UG, Pro/E, AutoCAD, and SolidWorks to create detailed and precise mould designs, ensuring every specification is accurately met.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Die and Mould Category

Speaker Grill Door Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Tolerance : 0.01 mm

Shaping Mode : Other, Injection Mould

Mould Base : P20 Steel

Working Process : Other, CNC Machining, EDM, Milling

Plastic Die and Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Tolerance : 0.01 mm

Shaping Mode : Other, Plastic Injection Mould

Mould Base : Steel, Standard Mould Base

Working Process : Other, Injection Moulding

Headlight Die

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Tolerance : 0.01 mm for tight dimensional accuracy.

Shaping Mode : Other, Injection Mold Shaping for accurate and repeatable headlight housings.

Mould Base : Mild Steel (MS), Precisely machined base plate offers high stability and durability.

Working Process : Other, Injection Molding and Precision Machining processes.

Tail Light Mould

Minimum Order Quantity : 1 Piece

Tolerance : 0.01 mm

Shaping Mode : Other, Injection Mould

Mould Base : 45# Steel (customizable as per requirement)

Working Process : Other, CNC Machining, EDM, Polishing, Heat Treatment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS