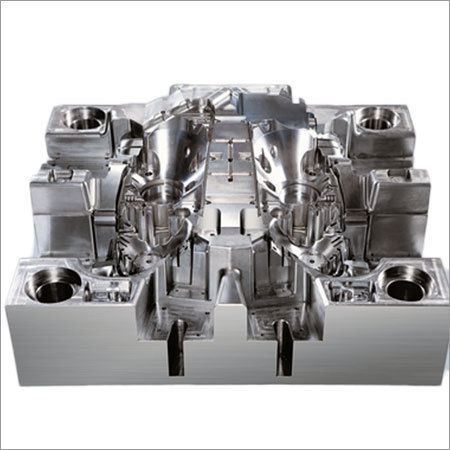

Tail Light Mould

Tail Light Mould Specification

- Life Span

- 500,000 to 1,000,000 shots

- Mould Base

- 45# Steel (customizable as per requirement)

- Core Material

- P20, 718, H13 or S136 (optional as per product and volume)

- Working Process

- CNC Machining, EDM, Polishing, Heat Treatment

- Tolerance

- 0.01 mm

- Material

- High-quality steel alloy (selected per application)

- Shaping Mode

- Injection Mould

- Punch Dies

- Custom-fit to design, Hardened steel

- Die Head

- Precision machined, High longevity steel

- Mould Size

- Customized to part specifications

- Application

- Automotive Lighting Component Manufacturing

- Lead Time

- 35-55 days

- Mould Weight

- Depends on design and application

- Cooling System

- Optimized Water Channel Layout

- Color

- As per customer specification

- Compatibility

- Suitable for use with most thermoplastic resins

- Runner Type

- Hot Runner/Cold Runner (as required)

- Surface Finish

- Mirror Polish

- Product Name

- Tail Light Mould

- Design Software

- UG, PRO/E, AutoCAD, SolidWorks

- Ejector System

- Pin/Blade Ejection

- Cavity Number

- Single or Multi Cavity (as per customer requirement)

Tail Light Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Week

About Tail Light Mould

Tail Light Mould that brought forward by us provides ideal dimension to tail light, which is utilized in a lots of vehicles like cars, tempo, motorcycles and so forth. Made of Grade-A metal with advanced die-casting technique, it is it fitted to Injection Moulding Machine as a key part. It has fine edges finish and perfect shape that allow to cast optimum quality light. In addition, the Tail Light Mould is robust enough to bear great impact while moulding work.

| Usage/Application | Molding Die |

Superior Engineering for Automotive Applications

Tail Light Moulds are crafted using top-grade materials such as P20, 718, H13, or S136 steel, ensuring exceptional durability and reliability. The robust construction and advanced design methodologies help maintain precise tolerances and high-quality mirror polish finishes, meeting the exacting standards of automotive component production.

Tailored to Customer Specifications

Each Tail Light Mould is manufactured according to the clients specific requirements, including cavity number, runner type, and mould size. Customers can choose from a selection of ejection systems and steel grades for the core and mould base, ensuring perfect compatibility with the intended thermoplastic resin and product design.

FAQs of Tail Light Mould:

Q: How is the Tail Light Mould customized for different automotive lighting components?

A: The Tail Light Mould can be tailored in cavity numbers, runner types, mould size, and material choice according to the customers specifications. This ensures optimal fit, function, and performance for varied automotive lighting part designs.Q: What advanced processes are used in manufacturing the Tail Light Mould?

A: Production utilizes CNC machining, EDM, polishing, and heat treatment for precision. Design is facilitated by UG, PRO/E, AutoCAD, and SolidWorks software, which enables accurate modelling and efficient workflow integration.Q: When can customers expect delivery of a completed Tail Light Mould?

A: Lead time for the Tail Light Mould ranges between 35 to 55 days, depending on the complexity and specific customization requirements set forth by the customer.Q: Where is the Tail Light Mould manufactured and supplied?

A: Tail Light Mould is manufactured by experienced providers in India, catering to both local and international automotive manufacturers, ensuring high standards and timely delivery.Q: What is the process for selecting suitable materials and finishes for the mould?

A: Material and surface finish selection depends on product volume and design parameters. Options include P20, 718, H13, or S136 for core material, mirror polish for surface, and a customizable mould base, adapting the mould for longevity and application-specific needs.Q: How does the mould benefit automotive lighting component makers?

A: Tail Light Mould provides reliable operation, precise tolerances, optimized cooling, and a high-quality surface finish. It helps manufacturers achieve consistent production, reduced cycle times, and lower defects, ultimately enhancing the final products durability and appearance.Q: What thermoplastic materials can be used with this mould?

A: The mould is suitable for most thermoplastic resins, making it versatile for the production of various automotive lighting components meeting diverse OEM specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Die and Mould Category

Headlight Die

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Mould Base : Mild Steel (MS), Precisely machined base plate offers high stability and durability.

Core Material : Highgrade H13 Tool Steel, providing excellent hardness and thermal resistance.

Working Process : Other, Injection Molding and Precision Machining processes.

Tolerance : 0.01 mm for tight dimensional accuracy.

Speaker Grill Door Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Mould Base : P20 Steel

Core Material : H13 Steel

Working Process : Other, CNC Machining, EDM, Milling

Tolerance : 0.01 mm

Plastic Die and Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Mould Base : Steel, Standard Mould Base

Core Material : Hardened Tool Steel

Working Process : Other, Injection Moulding

Tolerance : 0.01 mm

Front Grill Mould

Minimum Order Quantity : 1 , , Piece

Mould Base : P20 Steel

Core Material : 718H Hardened Steel

Working Process : Other, CNC Machining, EDM, Polishing

Tolerance : 0.02 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS