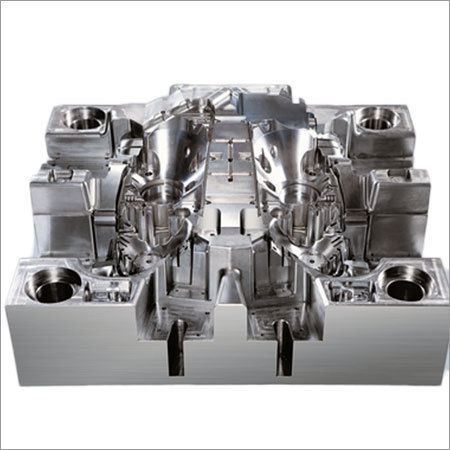

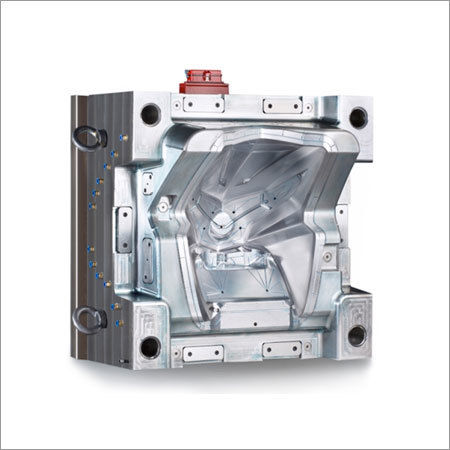

Plastic Die and Mould

Price 10000-1000000 INR/ Piece

Plastic Die and Mould Specification

- Tolerance

- 0.01 mm

- Working Process

- Injection Moulding

- Core Material

- Hardened Tool Steel

- Mould Base

- Steel, Standard Mould Base

- Life Span

- 300,000 - 1,000,000 shots

- Material

- Plastic/Metal as required

- Shaping Mode

- Plastic Injection Mould

- Punch Dies

- High-Strength Steel, Heat Treated

- Die Head

- Precision Machined, Customizable

- Mould Weight

- According to Design

- Application

- Automobile, Consumer Goods, Electronics

- Processing Type

- CNC Machining, EDM, Milling

- Surface Finish

- Polished, Textured or Custom

- Color

- Customized

- Design Software

- AutoCAD, UG, Pro/E, SolidWorks

- Lead Time

- 25-45 days

- Runner System

- Cold/Hot Runner

- Ejection System

- Automatic or Manual

- Cavity Number

- Single or Multi Cavity

Plastic Die and Mould Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

About Plastic Die and Mould

Versatile Applications for Every Industry

Plastic Die and Mould solutions play a vital role across various applications, including automobile manufacturing plants, electronics assembly lines, and consumer goods production facilities. With a celebrated reputation for precision and durability, these tools are engineered for plant usage where high-volume, flawless output is essential. Their adaptability to custom requirements makes them indispensable in sectors demanding immaculate finish and structural integrity, ensuring they remain a premier choice for large-scale and niche operations alike.

Sample Dispatch and Nationwide Service

Exchange of Plastic Die and Mould samples is available upon request, ensuring customers can scrutinize quality before full-scale procurement. Upon confirmed paymentsupported by flexible termsorders are promptly dispatched and securely shipped, guaranteeing timely arrival. Our celebrated services cater to the main domestic markets throughout India, making us a trusted supplier for businesses nationwide. Whether your project is a new launch or replacement, our clearance process ensures seamless procurement and swift arrival of products.

FAQs of Plastic Die and Mould:

Q: How do I choose the right runner system for my application?

A: Selecting between a cold or hot runner system depends on your product requirements, mould design, and budget. Our experts can guide you based on your specific needs for efficiency and material savings.Q: What is the process for ordering custom Plastic Die and Mould?

A: Start by sharing your design and requirements. Our team will provide consultation, finalize specifications, and proceed with procurement, manufacturing, and sample dispatch before full production begins.Q: Where can these dies and moulds be used most effectively?

A: They are ideal for use in automobile manufacturing, consumer goods production, and electronics assembly plants, thanks to their versatility and immaculate finish.Q: What is the typical lead time for delivery upon order confirmation?

A: The standard lead time ranges from 25 to 45 days, depending on the design complexity and customization requirements.Q: What are the benefits of using high-strength steel punch dies?

A: High-strength, heat-treated punch dies ensure greater durability, precise shaping, and a longer lifespan, making them a reliable choice for demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Die and Mould Category

Speaker Grill Door Mould

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Other, Plastic, Steel

Mould Base : P20 Steel

Life Span : 1,000,000 Shots

Tolerance : 0.01 mm

Headlight Die

Price 10000-1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Steel for die and core; compatible with both thermoplastic and thermoset molding.

Mould Base : Mild Steel (MS), Precisely machined base plate offers high stability and durability.

Life Span : Up to 500,000 cycles (depends on maintenance and material used).

Tolerance : 0.01 mm for tight dimensional accuracy.

Motorcycle Front Cover Mould

Minimum Order Quantity : 1 Piece

Material : Other, Plastic/ABS/PC

Mould Base : Standard P20 or as per customer requirement

Life Span : 300,000 500,000 shots

Tolerance : 0.01 mm

Tail Light Mould

Minimum Order Quantity : 1 Piece

Material : Other, Highquality steel alloy (selected per application)

Mould Base : 45# Steel (customizable as per requirement)

Life Span : 500,000 to 1,000,000 shots

Tolerance : 0.01 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS